Rope Infos

Rope Constructions

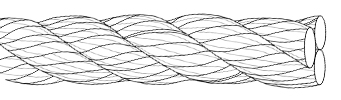

3-Strand

3-Strand ropes have been produced since the early days of rope making. They are what you picture when you think of a traditional rope. Their appearance is similar to ‘soft serve’ ice cream. The ropes are made with a special stabilization process and a solid, balanced construction. This way they become durable, long-lasting, flexible and easy-to-handle. Another advantage is, that these 3-strand ropes that won’t harden with age.

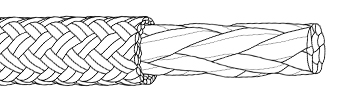

Single braid

Single braid ropes are made of a supple construction that absorbs twist. It does not kink but provided great ease of splice due to its simple construction. These ropes have a braided outside with no core. They are also known as ‘hollow braid’.

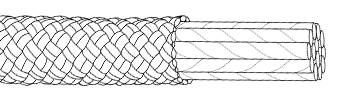

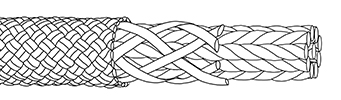

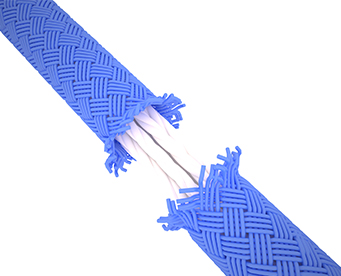

Double braid

Double braid ropes feature a braided core inside a braided cover. The core makes the rope strong and durable yet easy to handle. Since the rope consists of two individual parts, it is possible to combine different fibers to create ropes merging specific characteristics of different raw materials. For example, a high tensile core with a heat resistant cover. These ropes are similar to kernmantle ropes, however they are spliceable.

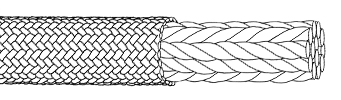

Kernmantle

Kernmantle ropes are the most common construction for dynamic climbing ropes. They feature a tight 32carrier, 40carrier or 48carrier cover to protect the core from any ingress of dirt or particles that might harm the core. The sheath is designed to generate some grab and friction for rappelling and lowering operations. The core is comprised of straight bundles of fiber that are loosely twisted. These bundles help to keep the rope firm yet flexible. The amount of twist in the core fibers in one of the main characteristics that dictate whether the rope is static or dynamic.

PLATINUM

PLATINUM® is the name of TEUFELBERGER’s patented and innovative braiding technology. Ropes with the PLATINUM® technology feature a permanent, mechanical connection between core and cover. Moreover,Additionally, PLATINUM® connects parallel cores to one another. This interconnection of the independent elements of a rope result in a compact rope with good handling and a plus in safety.

Str8 Jacket

Ropes with Str8 Jacket Core construction feature an intermediate layer of fibers between the core and the cover. These fibers allow the rope to hold its shape better, keep cover and core in balance and therefore, eliminating sheath slippage. This construction is used in MAXIM®’s Chalk Lines to avoid sheath slippage in heavy top rope use.

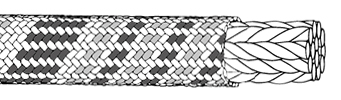

TPT-Technology

MAXIM’s Twill Pattern Technology (TPT) is a special cover design resulting in a twill pattern (one over one) or weave. Due to this design the cover has a smaller profile in cross-section than plain pattern ropes – the more traditional-looking climbing rope cover (two over two). A result of the smaller profile is improved abrasion resistance over abrasive surfaces, as well as significantly reduced drag in carabiners and mechanical devices. That’s why climbers use TPT-ropes for long rope lengths where drag should be reduced.

Bi-Pattern

Bi-Pattern ropes follow a special design that changes pattern at the rope’s midpoint. This change is a result of repositioning the bobbins (spools) during the braiding process to permanently mark the center of the rope in a way. The marking is immediately visible to the climber and since no fibers are cut, tied or spliced and no pigments or other chemicals are applied to mark the middle points, Bi-Patterns are the safest form of mid-point marking available for climbing ropes.

Rope Types

Before you are able to decide which rope to choose for your climbing experience, it is essential know about available climbing rope types. The most popular climbing ropes are single ropes, which are mainly used for sport and indoor climbing. For trad, multi-pitch, alpine or ice climbing, half or twin ropes are preferred and for hauling often static ropes are chosen.

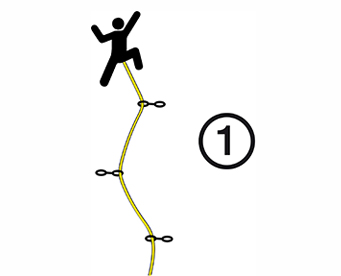

Single rope

Single ropes are the most common type of climbing ropes and have many uses. They are used for top rope climbing, sport and trad climbing as well as indoor and gym climbing. Single ropes are used in a single strand, therefore the handling is very simple and easy.

Standard single ropes range from about 9.5mm to 11mm in diameter. High end single rope are thinner with a diameter around 9mm and smooth covers.

Single ropes are tested in a single strand according to the UIAA standard, which references EN 892 with a test mass of 80 kg. They need to withstand a minimum of 5 falls and the maximum impact force must not exceed 12 kN.

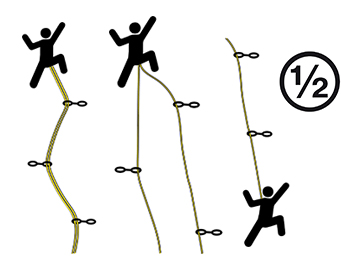

Half rope

Half ropes range from about 7.9mm to 9mm diameter, are lightweight and most of the time dry-treated. That’s why they are mainly used for ice climbing, alpine climbing or mountaineering.

Half ropes are tested in a single strand according to the UIAA standard standard, which references EN 892 with a test mass of 55 kg. They need to withstand a minimum of 5 falls and the maximum impact force must not exceed 8 kN. The lower mass is used because it is assumed that half ropes normally share the load between both strands.

Twin rope

Twin ropes range from 6.9mm to 9mm diameters. Twin ropes are often even lighter and thinner than half ropes.

Twin ropes are tested in a double strand according to standard EN 892 with a test mass of 80 kg. They need to withstand a minimum of 12 falls and the maximum impact force must not exceed 12 kN.

Rope Material

Synthetic fibers have different shapes that influence their characteristics and performance. Monofilaments are endless thick fibers with a stiff structure that offer very good abrasion resistance and low dirt take-up. Multifilaments are a bundle of thin fibers which are processed into twines before braiding a rope out of them. Most fibers follow this design which leads to high flexibility and tensile strength. Textured fibers are based on natural fibers and show a certain degree of disorder which gives the fibers good grip and high elasticity. The last type of fibers are Staple fibers which consist of spun pieces of short filaments. This construction gives the fiber excellent grip and soft handling.

Fiber structures

- Synthetic fibers have different shapes that influence their characteristics and performance

- Monofilaments are endless and thick fibers with a stiff structure that offer very good abrasion resistance and low dirt take-up

- Multifilaments are a bundle of thin fibers which are processed into twines before braiding a rope out of them. Most fibers follow this design which leads to high flexibility and tensile strength.

- Textured fibers are based on natural fibers and show a certain degree of disorder which gives the fibers good grip and high elasticity.

- Staple fibers consist of spun pieces of short filaments. This construction gives the fiber excellent grip and soft handling.

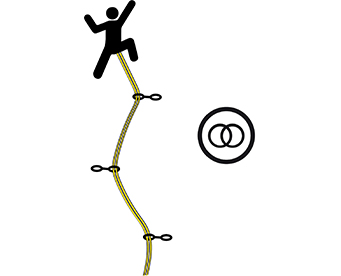

Raw Material

Nylon (NY) / Polyamide (PA)

Polyamide or better known under its trade name Nylon, has high breaking load as well as high elongation. Preferably, it is used in products that are required to absorb shock loads like dynamic climbing ropes. The abrasion resistance of nylon is better in wet conditions than in dry conditions because it tends to take up water (up to 7%). Kept in wet conditions for too long, the material can become stiff. Another disadvantage compared to polyester is the lower resistance to UV-radiation in sunlight.

Polyester (PES)

Polyester is mainly used for static ropes because Polyester is characterized by good breaking loads and low stretch. This material offers both chemical and physical advantages such as UV resistance salt water resistance, and good abrasion strength in both dry and wet conditions. However, the dynamic energy absorption capacity is much lower than that of nylon ropes and therefore only to a limited extent suitable for types of use involving high impact forces.

Ultra High Molecular Weight Polyethylene (UHMWPE)

UHMWPE (also known as UHMPE or HMPE Dyneema®) is an extremely high strength fiber of ultra high molecular polyethylene. For the same weight it has 15 times the tensile strength of steel. Rope or slings made from this type of fiber shows very low elongation and tensile strength. If very high loads are being applied for a long period of time, UHMWPE fiber tends to creep. The rope then is irreversibly extending its length. At the same time, these robust fibers show excellent performance in terms of abrasion resistance and good UV-resistance.

Aramid (Aromatic Nylon)

Aramid fibers have an extremely high breaking load and show almost no stretch. On the other hand they are sensitive to UV-rays, bending over sharp edges, and abrasion. It is mainly used in places where high temperature resistance and abrasion is essential, for example on winches, in hot air balloon ropes or for canyoneering where the rope is nearly always in contact with rough stones.

Polypropylene (PP)

Due to its limited technical characteristics, polypropylene is only used for simple applications. PP is very light and even buoyant in water, that’s why it is used for water throwlines. Its abrasion resistance and temperature resistance are lower than those of most other fibers.

Technologies

MAXIM® Climbing ropes always strives to offer cutting-edge products in terms of technology and design. Therefore we came up with some new technology that revolutionized the rope market within the last years and add value to our products. Find out more about the MAXIM® technologies.

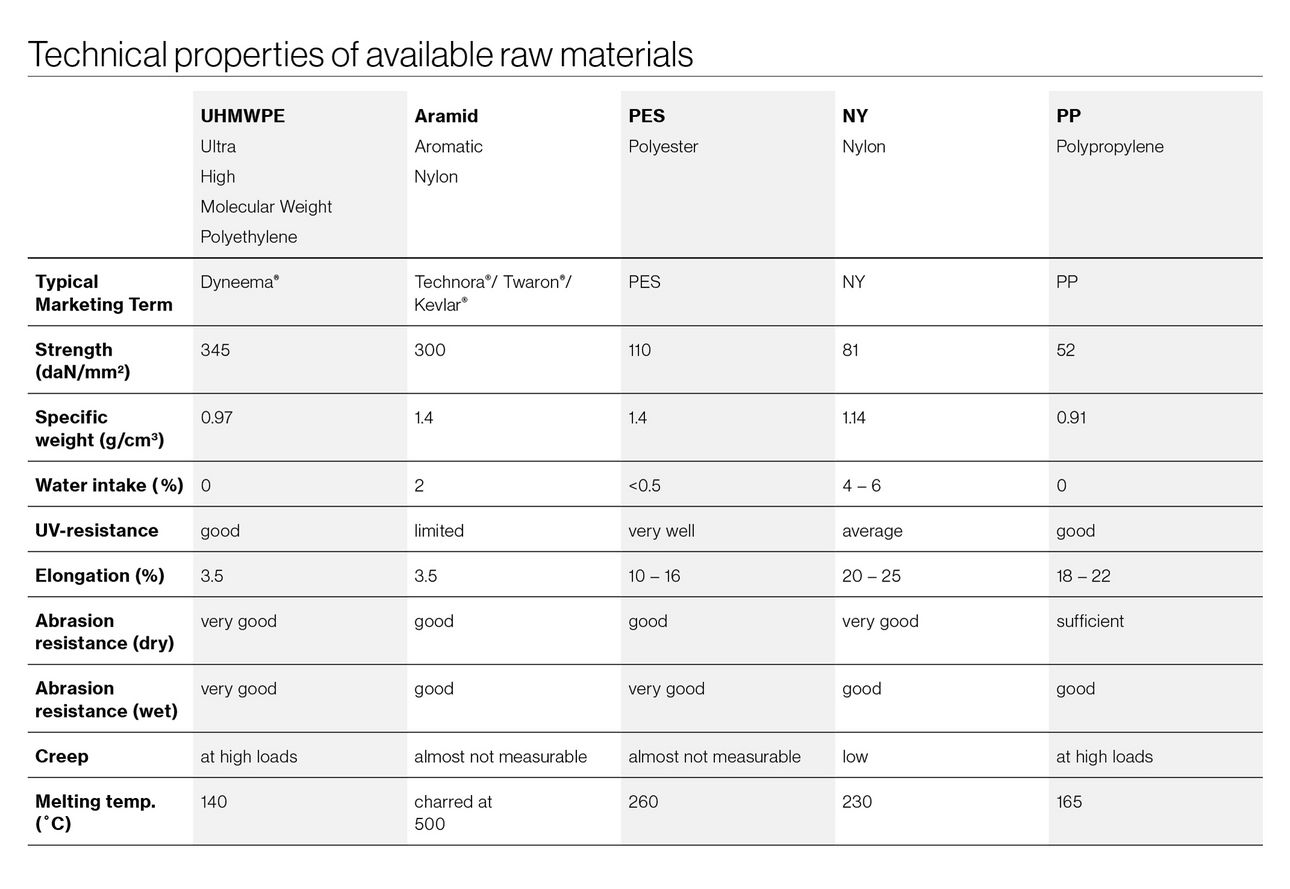

Platinum Technology

The PLATINUM® technology offers the ultimate in safety & security. In contrast to conventional kernmantle ropes, ropes with the PLATINUM® technology feature a permanent mechanical connection between the rope‘s core and its cover. At regular intervals, the core and cover yarns are interlaced with one another, which avoids sheath slippage.

Additionally, the twisted cores are mechanically connected to produce a stable and compact core where load is equally distributed. These features result in a compact yet flexible rope with superior handling and high abrasion resistance. The connection of the two load-bearing elements makes PLATINUM® ropes an especially safe choice in abrasive and sharp-edged surroundings. In case the cover is cut at a sharp rock edge, the core and the cover remain bonded together and the cover will not slip.

Due to its special construction, ropes with the PLATINUM® technology offer a solution to the following critical situations in traditional rope usage:

Coreless cover at the end

Sheath slippage can cause a surplus length of the cover at the end of the rope that results in a coreless rope section. This may be extremely dangerous for inexperienced climbers. PLATINUM® technology avoids core-cover displacement!

Conventional rope

PLATINUM rope

Pushing together of cover

The use of climbing devices might push the cover of traditional ropes together and make it impossible to pass the rope through the device; climbers would no longer able to rappel down by themselves. PLATINUM® technology prevents bunching of the cover!

Conventional rope

PLATINUM rope

Sheath severing

In contact with sharp edges, the cover of the rope could get cut and break. With traditional ropes, the cover slides down, gathers and in the best case makes it difficult to pass, in the worst case the cover will slide completely off the rope. PLATINUM® technology keeps core and cover together due to permanent mechanical connection, even if the sheath is severed in 360 degrees around the rope.

Conventional rope

PLATINUM rope

The PLATINUM® technology was developed by TEUFELBERGER. in 2012, and was only used for semi-static ropes initially. It took another five years to transfer this unique technology to dynamic climbing ropes. In 2017, we were finally able to introduce the first climbing rope with the special core-cover-connection to the market, MAXIM PLATINUM®. On top of the patented PLATINUM® interconnection of core and cover and its other advantages, MAXIM PLATINUM® offers additional features like a Middle Mark and a Warning Track Tracer that offer the ultimate in safety & durability.

Downloads

MAXIM Platinum Folder

Catalog

543 KB

User instruction PLATINUM ropes

User instruction

1.8 MB

Manufacturer information MAXIM PLATINUM

Manufacturer information

449 KB

Endura Dry Treatment

Climbing ropes are made of nylon, which takes up water and results in heavier and stiffer ropes. In order to avoid water intake, MAXIM® developed Endura DRY, a multi-stage application process to protect MAXIM® ropes against water. However, Endura DRY does more than keeping water out of the rope. The coating also lubricates individual core fibers to improve the resistance to internal abrasion that can occur beneath the surface.

Endura STD-DRY

Standard (STD) dry ropes run through the first stage of the process where water-repellent coating is applied to the individual core yarns prior to the braiding process. All MAXIM® ropes have STD-DRY treated cores surrounded by a durable, protective nylon sheath to lock in the water-blocking power of the coating. This includes our indoor gym ropes. Your safety comes first at Maxim.

Endura 2x-DRY

Select models of MAXIM® ropes also pass the second stage of the Endura DRY process and feature 2x-DRY treatment. These ropes are treated a second time by submerging the finished rope in our proprietary dry coating. Afterwards, the finished rope runs through an environmentally controlled process to create a chemical bond between coating and fibers.

MAXIM® ropes with Endura 2x-DRY treatment takes in less than 5 % of their weight in water. Therefore, they also fulfill the requirements to be marked as UIAA water-repellent according to UIAA standard 101.