ROPE CONSTRUCTIONS

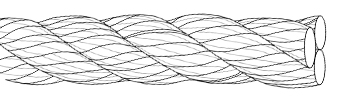

3-strand

3-Strand ropes have been produced since the early days of rope making. They are what you picture when you think of a traditional rope. Their appearance is similar to ‘soft serve’ ice cream. The ropes are made with a special stabilization process and a solid, balanced construction. This way they become durable, long-lasting, flexible and easy-to-handle. Another advantage is, that these 3-strand ropes that won’t harden with age.

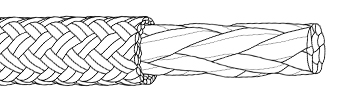

Single braid

Single braid ropes are made of a supple construction that absorbs twist. It does not kink but provided great ease of splice due to its simple construction. These ropes have a braided outside with no core. They are also known as ‘hollow braid’.

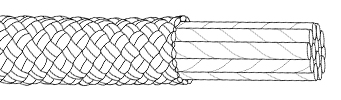

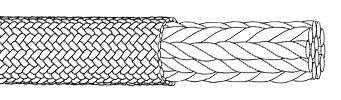

Double braid

Double braid ropes feature a braided core inside a braided cover. The core makes the rope strong and durable yet easy to handle. Since the rope consists of two individual parts, it is possible to combine different fibers to create ropes merging specific characteristics of different raw materials. For example, a high tensile core with a heat resistant cover. These ropes are similar to kernmantle ropes, however they are spliceable.

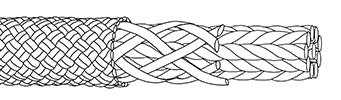

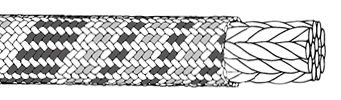

Kernmantle

Kernmantle ropes are the most common construction for dynamic climbing ropes. They feature a tight 32carrier, 40carrier or 48carrier cover to protect the core from any ingress of dirt or particles that might harm the core. The sheath is designed to generate some grab and friction for rappelling and lowering operations. The core is comprised of straight bundles of fiber that are loosely twisted. These bundles help to keep the rope firm yet flexible. The amount of twist in the core fibers in one of the main characteristics that dictate whether the rope is static or dynamic.

PLATINUM

PLATINUM® is the name of TEUFELBERGER’s patented and innovative braiding technology. Ropes with the PLATINUM® technology feature a permanent, mechanical connection between core and cover. Moreover,Additionally, PLATINUM® connects parallel cores to one another. This interconnection of the independent elements of a rope result in a compact rope with good handling and a plus in safety.

Explore more about our PLATINUM® Technology

Str8 Jacket

Ropes with Str8 Jacket Core construction feature an intermediate layer of fibers between the core and the cover. These fibers allow the rope to hold its shape better, keep cover and core in balance and therefore, eliminatinge sheath slippage. This construction is used in MAXIM®’s Chalk Llines to avoid sheath slippage in heavy top rope use.

TPT-Technology

MAXIM’s Twill Pattern Technology (TPT) is a special cover design resulting in a twill pattern (one over one) or weave. Due to this design the cover has a smaller profile in cross-section than plain pattern ropes - the more traditional-looking climbing rope cover (two over two). A result of the smaller profile is improved abrasion resistance over abrasive surfaces, as well as significantly reduced drag in carabiners and mechanical devices. That’s why climbers use TPT-ropes for long rope lengths where drag should be reduced.

Bi-Pattern

Bi-Pattern ropes follow a special design that changes pattern at the rope’s midpoint. This change is a result of repositioning the bobbins (spools) during the braiding process to permanently mark the center of the rope in a way. The marking is immediately visible to the climber and since no fibers are cut, tied or spliced and no pigments or other chemicals are applied to mark the middle points, Bi-Patterns are the safest form of mid-point marking available for climbing ropes.

Trad/Sport climbing

Trad/Sport climbing

Top Rope

Top Rope

Gym climbing

Gym climbing

Ice climbing

Ice climbing

Alpine/Mountaineering

Alpine/Mountaineering

Challenge Course

Challenge Course

Big Wall

Big Wall

Caving/Canyoneering

Caving/Canyoneering

Military/First responders

Military/First responders

Climbing Photography

Climbing Photography

Bouldering

Bouldering